What Is An Induction Heating Machine?

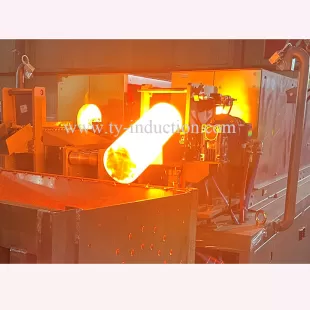

Induction heating is the process of heating electrically conductive materials, namely metals or semi-conductors, by electromagnetic induction, through heat transfer passing through an induction coil that creates an electromagnetic field within the coil to heat up and possibly melt steel, copper, brass, graphite, gold, silver, aluminum, or carbide.

Tianyuan induction heating systems Company has operating frequency, magnetic materials, depth of penetration, coupling efficiency and coil design.

Heat losses and uneven, inconsistent application of heat result in increased scrap and diminished product quality, driving up per-unit costs and consuming profits. Best manufacturing economies are seen when the application of energy is controlled.

To bring a batch oven up to temperature and to hold the entire chamber at the required temperature for the process time demands much more energy than is required to process the parts. Flame-driven processes are inherently inefficient, losing heat to the surroundings. Electrical resistance heating can also result in the wasteful heating of surrounding materials. Applying only the energy needed to process your parts is ideal.

Induction selectively focuses energy only on the area of the part that you want to heat. Each part in a process enjoys the same efficient application of energy. Since the energy is transferred directly from the coil to a part, there is no intervening media like flame or air to skew the process.

The precision and repeatability of induction heating help to reduce process scrap rate and to improve throughput. The selective application of heat to the targeted area of a part enables very tight control of the heating process, also cutting the heating time and limiting energy requirements.

评论

发表评论